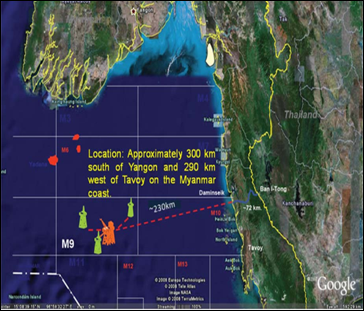

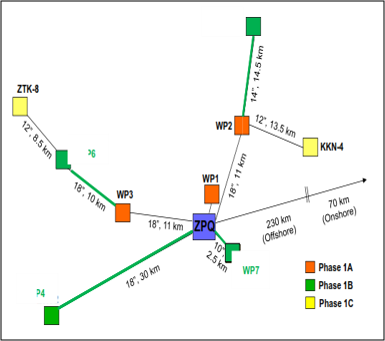

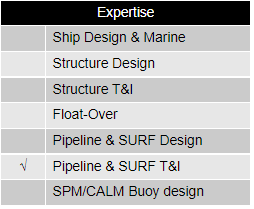

Client: | PTTEP International Limited |

Project: | Zawtika Development Project Phase 1 A |

Location: | Myanmar |

Period: | 2013 |

WD: | 0-160 meters |

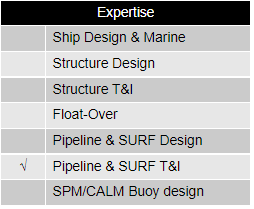

Work Scope:

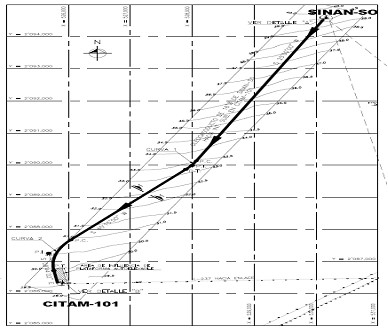

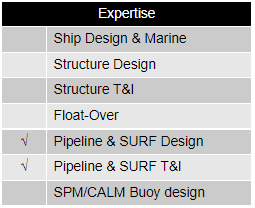

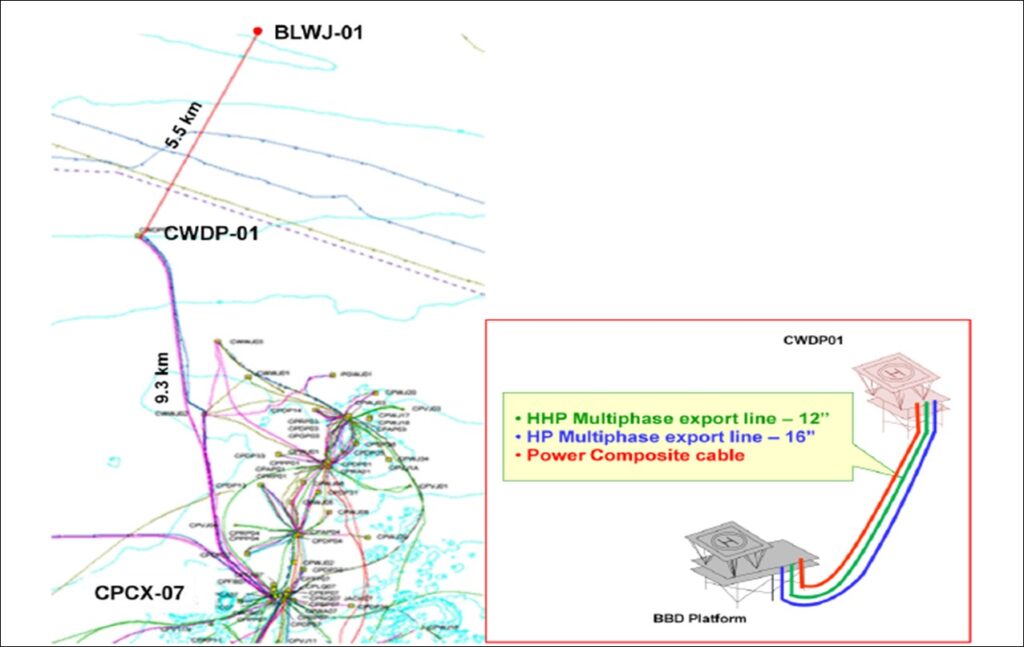

Client: | PEMEX EXPLORACION Y PRODUCCION |

Project: | INGENIERÍA, PROCURA Y CONSTRUCCIÓN DE UN OLEOGASODUCTO DE 16″ Ø X 9.3 KM. DE LA PLATAFORMA SINAN SO A LA INTERCONEXIÓN SUBMARINA DEL DUCTO DE 16″ DE CITAM-101 A ENLACE, ASÍ COMO OBRA ELECTROMECÁNICA, A INSTALAR EN LA SONDA DE CAMPECHE, GOLFO DE MÉXICO |

Location: | Mexico |

Period: | 2013 |

WD: | 30-40 meters |

Work Scope:

9.48km 16-in (406.4 mm) pipeline coated with 1-in (25.4 mm) concrete will transport hydrocarbon from Sinan SO platform to Citam 101

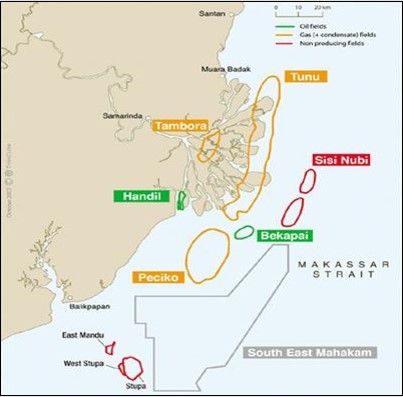

Client: | TOTAL E&P Indonesie |

Project: | TOTAL E&P Indonesia – Sisi Nubi Phase 2B & Peciko 7B Project |

Location: | Indonesia |

Period: | 2014 |

WD: | 60-80 meters |

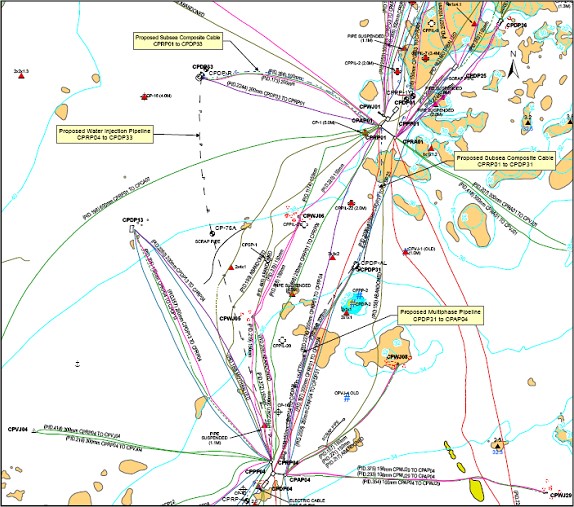

Work Scope:

Supervision and 3rd party verification of Detailed Pipeline Design (by JP Kenny) Transportation & Installation Engineering

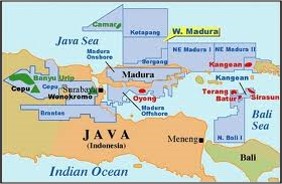

Client: | PT. Pertamina Hulu Energi West Madura Offshore |

Project: | PHE-WMO – KE-39, KE-54, KE-40 and KE-38B Platforms and Pipelines EPCI |

Location: | Indonesia |

Period: | 2013 |

WD: | 60 meters |

Work Scope:

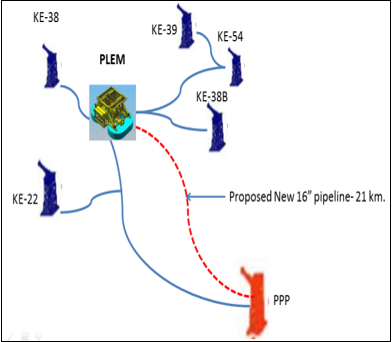

Client: | PT Pertamina Hulu Energi – West Madura Offshore |

Project: | PHE WMO – 16” Offshore Pipeline Installation from KE-38P Manifold to PPP |

Location: | Indonesia |

Period: | 2013 |

WD: | 58 meters |

Work Scope:

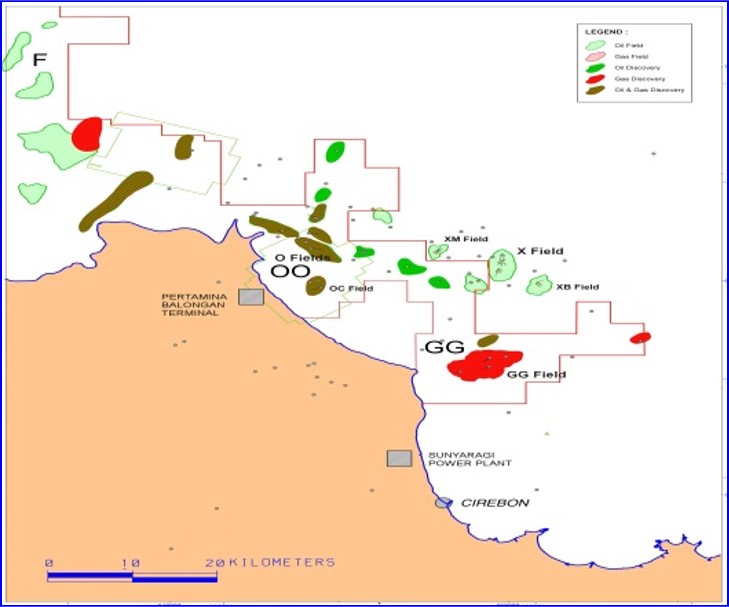

Client: | PT. Pertamina Hulu Energi – Offshore North West Java |

Project: | EPCI for GG New Development Project |

Location: | Indonesia |

Period: | 2013 |

WD: | 7-21 meters |

Work Scope:

Client: | Petronas Carigali Sdn Bhd |

Project: | Offshore Transportation, Installation and Pre-commissioning of Pipeline & SPMs for SOGT Project |

Location: | Indonesia |

Period: | 2013 |

WD: | 29 meters |

Work Scope:

Client: | Brunei Shell Petroleum |

Project: | Champion Water Flood Project |

Location: | Brunei |

Period: | 2013 |

WD: | 40 meters |

Work Scope:

Client: | Premier Oil |

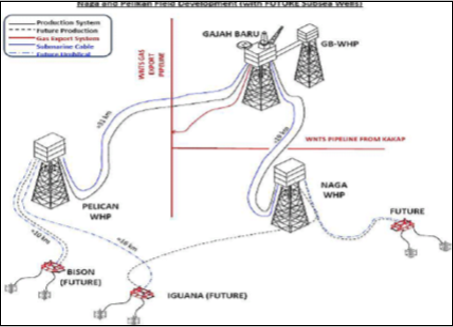

Project: | Naga Pelikan Pipeline / SURF Project |

Location: | Indonesia |

Period: | 2012 |

WD: | 82 meters |

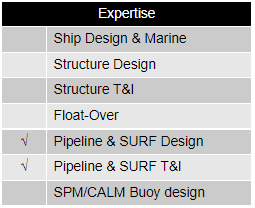

Work Scope:

Client: | ConocoPhillips Indonesia Inc. Ltd. |

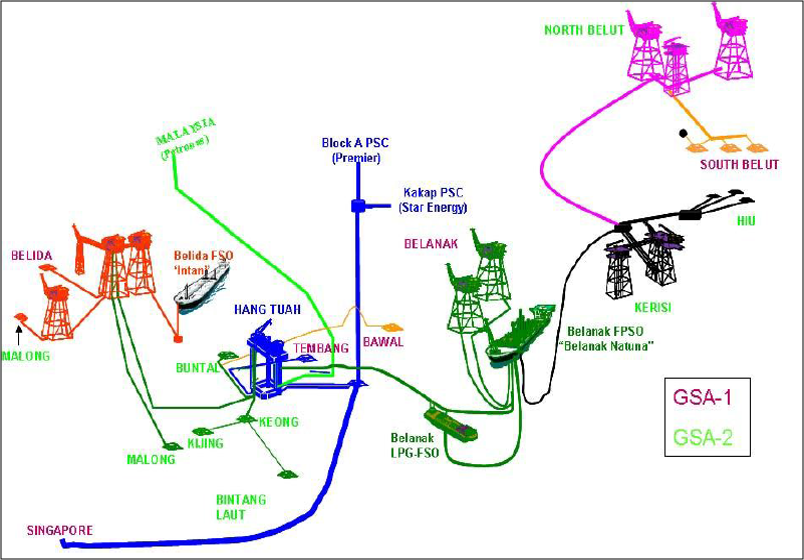

Project: | COPI – South Belut Subsea and Topsides Facilities EPCI |

Location: | Indonesia |

Period: | 2012 |

WD: | 100 meters |

Work Scope:

Client: | ConocoPhillips Indonesia Inc. Ltd. |

Project: | BAWAL – Umbilical – Flowline |

Location: | Indonesia |

Period: | 2012 |

WD: | 70 meters |

Work Scope:

Phase 2:-

Client: | Brunei Shell Petroleum |

Project: | Bulan-Bulan Development Project |

Location: | Brunei |

Period: | 2012 |

WD: | 60 meters |

Work Scope:

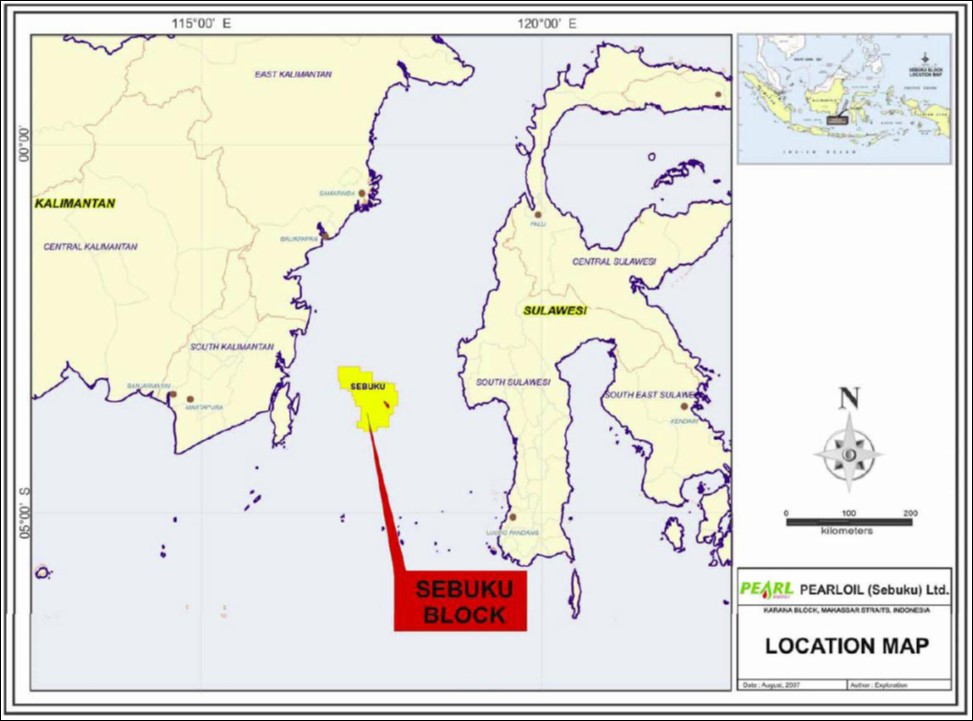

Client: | Pearl Oil |

Project: | PEARL OIL (SEBUKU) Pipeline Installation Program (R-263) |

Location: | Indonesia |

Period: | 2012 |

WD: | 71 meters |

Work Scope:

Client: | Brunei Shell Petroleum |

Project: | Pipeline Replacement Project 2 |

Location: | Brunei |

Period: | 2009 |

WD: | 27 meters |

Work Scope:

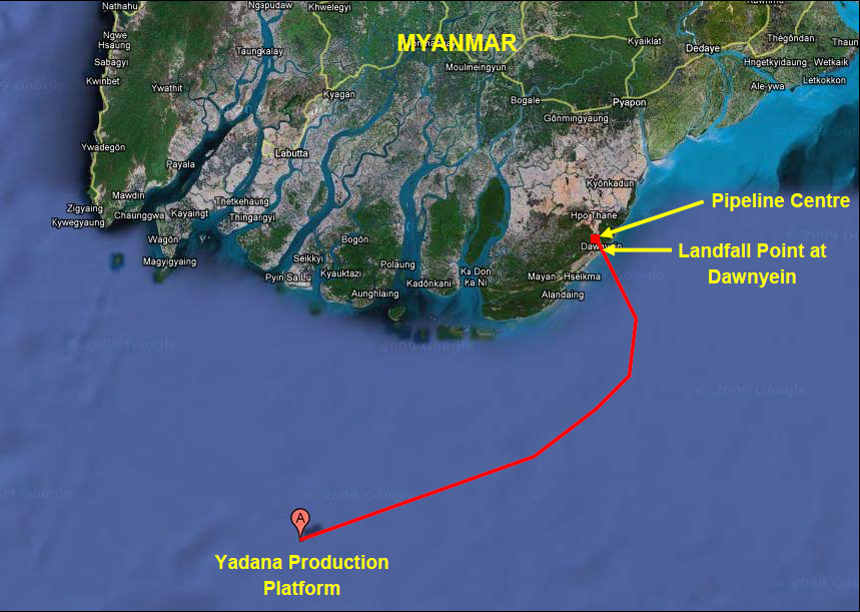

Client: | UNOG Pte Ltd / Myanma Oil and Gas Enterprise (MOGE) |

Project: | 24” Yadana Domestic Gas Pipeline Project |

Location: | Brunei |

Period: | 2009 |

WD: | 40 meters |

Work Scope:

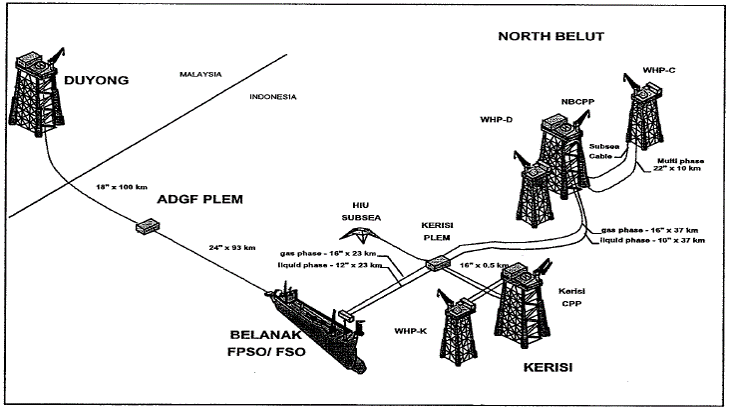

Client: | ConocoPhillips Indonesia Inc. Ltd. |

Project: | COPI – North Belut Subsea Pipeline Installation |

Location: | Indonesia |

Period: | 2008 |

WD: | 100 meters |

Work Scope: