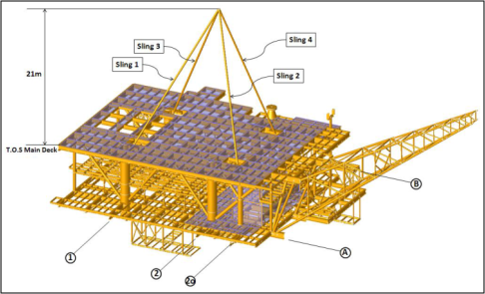

Client: | PT. Pertamina Hulu Energi West Madura Offshore |

Project: | PHE-WMO – KE-39, KE-54, KE-40 and KE-38B Platforms and Pipelines EPCI |

Location: | Indonesia |

Period: | 2013 |

WD: | 60 meters |

Work Scope:

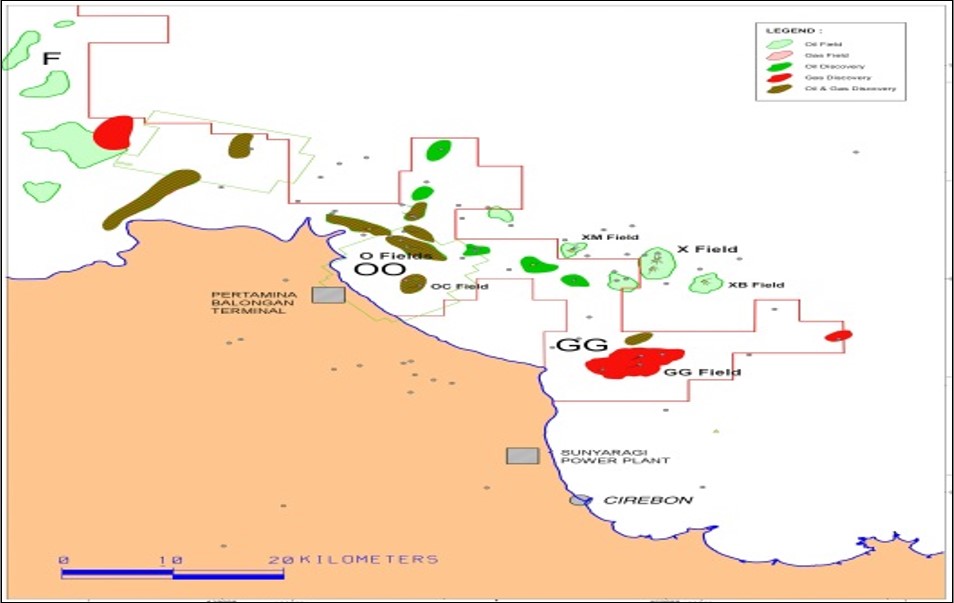

Client: | PT. Pertamina Hulu Energi – Offshore North West Java |

Project: | EPCI for GG New Development Project |

Location: | Indonesia |

Period: | 2013 |

WD: | 7-21 meters |

Work Scope:

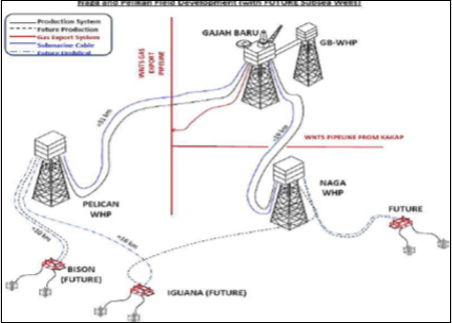

Client: | Premier Oil |

Project: | Naga Pelikan Pipeline / SURF Project |

Location: | Indonesia |

Period: | 2012 |

WD: | 82 meters |

Work Scope:

Client: | Brunei Shell Petroleum |

Project: | Bulan-Bulan Development Project |

Location: | Brunei |

Period: | 2012 |

WD: | 60 meters |

Work Scope:

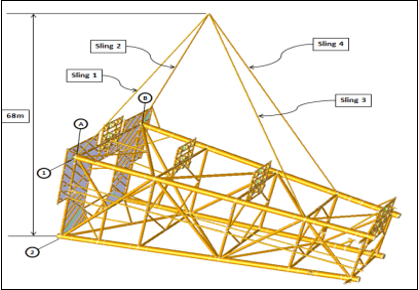

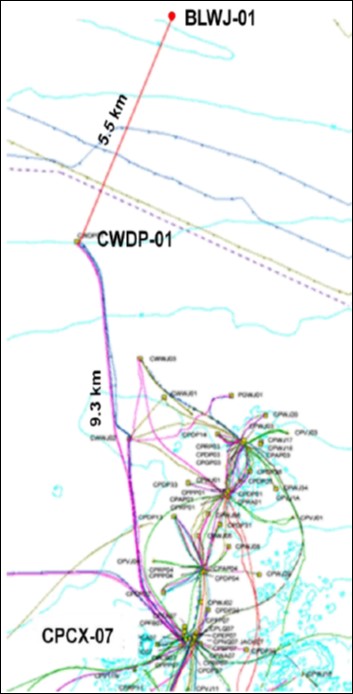

Client: | ConocoPhillips Indonesia Inc. Ltd. |

Project: | North Belut Project |

Location: | Indonesia |

Period: | 2008 |

WD: | 96 meters |

Work Scope:

Engineering of transportation and Installation of:

Client: | Oil & Natural Gas Co-orperation (ONGC) |

Project: | B-193 Process Platform (Topside Float Over Installation) |

Location: | India |

Period: | 2011 |

WD: | 60-75 meters |

Work Scope:

Client: | Petronas Carigali Turkmenistan Snd Bhd |

Project: | Central Diyarbekir Drilling platform (Turkmenistan) |

Location: | Middle East |

Period: | – |

WD: | 60-75 meters |

Work Scope:

Singapore

1 Jalan Kilang Timor, #06-01 Pacific Tech Centre. Singapore 159303

Email info@pape.engineering